|

Ma'anshan Baiyun Co. Ltd

|

mining tools

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

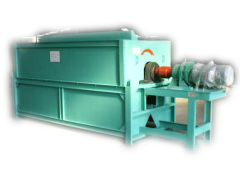

CTB Wet Drum Separator is newly developed iron ore concentrating equipment under wet conditions.

This kind of magnetic separator can provent the final product from the secondary contamination because of the washing action adopted in the processing. It is equipped with a respective spray pipe for feed and concentrates, and water amount can be adjusted so as to assure suitable density of the concentrate. It can be equipped with cocurrent, counter-rotation and counter current tanks, and equipped double drums or three drums according to requirements of customers.

Magnet System

This is the most critical part of any wet drum design, ours reflect many years of experience and development.

Our products adopt squeezed multiple-pole magnetic circuit, which can make magnetic field distrabuted so stable and reasonable that it can not only save energy, but also separate and purify the feed more efficiently.

The magnetic separation zone is comprised of stationary permanent magnet, with ferrite/cerimac magnet or rare earth magnets(NDFeB).

Drum Construction

The main cover is in stainless steel, as is the replaceable wearing cover----the drum can be covered with wearable rubber.Stainless steel end flanges have inner and outer seals ensuring the cover and flange joints are watertight.Sealed for life proprietory, flange bearings have grease nipples fitted and are protected from the slurry running down the flange .The magnet yoke and drum position can be easily adjusted to optimized mass recovery and process performance. The magnet yoke position can be adjusted I + 20 degree by a lever mounted at the end of the drum shaft. The bottle neck (gap between tank and drum surface) can be adjusted vertically by shims and horizontally by slotted holes, bringing the magnet poles as close as possible to the media and ensuring maximum magnetic field strength.

Tanks Design

The design of the magnetic separator tank is very important. It must take into account: a) presentation of the feed to the drum b) removal of the non-magnetic fraction c) nature of the washing action to be adopted.

While many variations exist in tank design, there are three basic groups, based on the pulp flow, as follows: I) concurrent II) counter-rotation III) counter-current

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!